|

Just like any other North American car made after

1996, the Diablo has an On Board Diagnostic or "OBDII socket" for a OBDII scan

tool. Government mandated rules specify that after the check engine

warning light comes on due to a fault, the engine control unit must record a

specific error code. The purpose of this code is to give precise information to

the service technician concerning the fault to allow its repair.

|

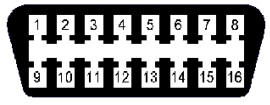

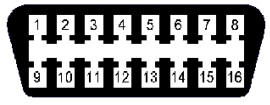

Fig 1 OBDII Socket Pins |

-

Pin 2 - J1850 Bus+

Pin 4 - Chassis Ground

Pin 5 - Signal Ground

Pin 6 - CAN High (J-2284)

Pin 7 - ISO 9141-2 K Line

Pin 10 - J1850 Bus

- Pin 11 Airbag Controller

- Pin 12 ABS Controller

- Pin 14 - CAN Low (J-2284)

Pin 15 - ISO 9141-2 L Line

Pin 16 - Battery Power

|

While the parameters, or readings,

required by OBDII regulations are uniform, the auto manufacturers

had some latitude in the communications protocol they used to

transmit those readings to scanners. Naturally, each felt they had

the one true way, so we have three different OBDII communications

protocols in use.

- As a

rule of thumb, GM cars and light trucks use SAE J1850 VPW (Variable

Pulse Width Modulation).

- Chrysler products and all European and most

Asian imports use ISO 9141 circuitry.

- Fords use SAE J1850 PWM (Pulse

Width Modulation) communication patterns.

|

|

Unlike the Diablo, the Gallardo does not put out OBDII codes that are

compatible with older diagnostic readers.

The Gallardo issues information at the OBDII socket on the

CAN lines (Pins 6 & 14). For this reason if you wish to read error

information you must have one of the newer OBDII readers that understands the

CAN data lines. Most past recent cars are switching to this format and the

newer OBDII readers are being modified to understand it. I have not looked

into this area extensively yet. Currently I am using the "ElmScan

5 Scan Tool". There are a number of

software packages

that work with this unit. I like "PCMSCAN".

I had a bad experience with one called PRScan (no technical support). The

ElmScan interface connects to a laptop, so you can expect the software to evolve

over time. With the above setup you can get an enormous amount of real

time information about your engine. According to the Lamborghini Gallardo

technical manual the following engine codes are put out:-

|

|

Component/System

|

Fault code

|

Monitor Strategy

Description |

Primary malfunction

detection parameter |

Fault Activation range

|

Time length of the

fault |

Frequency of check

|

- CATALYST

SYSTEM EFF.

- Bank 1

|

P0420 |

Functional check

|

front/rear oxygen ratio

|

< 4 |

5 faults in 10 times

|

Once per driving cycle

|

- CATALYST SYSTEM

EFF.

- Bank 2

|

P0430 |

Functional check

|

front/rear oxygen ratio

|

< 4 |

5 faults in 10 times

|

Once per driving cycle

|

|

RANDOM MISFIRE

|

P0300 |

|

Random Misfire

detection |

|

|

|

-

RANDOM MISFIRE

- Bank1

|

P1305 |

Misfire detection with

exhaust Pressure sensor |

Misfire Index AND

Harmonics Amplitude of Exhaust pressure signal |

MI>Threshold AND HA Off

Range function of RPM and MAP |

1s |

Continuous |

|

RANDOM MISFIRE

Bank2 |

P1306 |

Misfire detection with

exhaust Pressure sensor |

Misfire Index AND

Harmonics Amplitude of Exhaust pressure signal |

MI>Threshold AND HA Off

Range function of RPM and MAP |

1s |

Continuous |

|

CYLINDER 1 MISFIRE

DETECTED |

P0301 |

Misfire detection with

exhaust Pressure sensor |

Misfire Index,

Harmonics Amplitude AND Phase of Exhaust pressure signal

|

MI>Threshold HA in

Range AND Phase in Range function of RPM and MAP |

1s |

Continuous |

|

CYLINDER 2 MISFIRE

DETECTED |

P0302 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 3 MISFIRE

DETECTED |

P0303 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 4 MISFIRE

DETECTED |

P0304 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 5 MISFIRE

DETECTED |

P0305 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 6 MISFIRE

DETECTED |

P0306 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 7 MISFIRE

DETECTED |

P0307 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 8 MISFIRE

DETECTED

|

P0308 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 9 MISFIRE

DETECTED

|

P0309 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

CYLINDER 10 MISFIRE

DETECTED

|

P0310 |

Misfire detection with

exhaust pressure sensor |

|

Same as P0301

|

|

|

|

|

Component/System |

Fault code |

Monitor Strategy

Description

|

Primary malfunction

detection parameter

|

Fault Activation range |

Time length of the

fault

|

Frequency of check |

-

EXHAUST PRESSURE SENSOR

- BANK 1

|

P1311 |

Functional check |

Exhaust sensor pressure

signal

|

MI < Threshold |

10 s |

Continuous |

|

P1312 |

Low input |

Exhaust sensor pressure

signal

|

< 0.5 V |

10 s |

Continuous |

|

P1313 |

High input |

Exhaust sensor pressure

signal

|

> 4.9 V |

10 s |

Continuous |

-

EXHAUST PRESSURE SENSOR

- Bank 2

|

P1314 |

Functional check |

Exhaust sensor pressure

signal

|

MI < Threshold |

10 s |

Continuous |

|

P1315 |

Low input |

Exhaust sensor pressure

signal

|

< 0.5 V |

10 s |

Continuous |

|

P1316 |

High input |

Exhaust sensor pressure

signal

|

> 4.9 V |

10 s |

Continuous |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

-

OXYGEN SENSOR FRONT

- Bank 1

|

P0133 |

Response Rate |

Switching frequency AND Quick output change

counter

|

S_FREQ < 15 or QOCC < 60

|

|

Once per driving cycle

|

|

P0134 |

Oxygen sensor inactive |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

60 s |

Continuous |

|

P2195 |

Oxygen sensor stuck lean |

Oxygen sensor output voltage

|

0.01 ≤ V < 0.4 |

30 s |

Continuous |

|

P2196 |

Oxygen sensor stuck rich |

Oxygen sensor output voltage

|

0.55 < V < 1.05 |

60 s |

Continuous |

|

P0131 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

< 0.01 V |

30 s |

Continuous |

|

P0132 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

≥ 1.05 V |

60 s |

Continuous |

-

OXYGEN SENSOR REAR

- Bank 1

|

P0140 |

Oxygen sensor inactive |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

60 s |

Continuous |

| |

Transient test |

Oxygen sensor output voltage

|

V> 0.5 |

10 times |

Continuous |

| |

|

|

V< 0.5 |

10 times |

Continuous |

|

P2270 |

Oxygen sensor stuck lean |

Oxygen sensor output voltag

|

0.01 ≤ V < 0.1 |

300 s |

Continuous |

|

P2271 |

Oxygen sensor stuck lean |

Oxygen sensor output voltag

|

0.07 < V < 1.05 |

300 s |

Continuous |

|

P0137 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

< 0.01 V |

300 s |

Continuous |

|

P0138 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

≥ 1.05 V |

300 s |

Continuous |

-

OXYGEN HEATER FRONT

- Bank 1

|

P0135 |

Functional check |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

5 s |

Once per driving cycle |

-

OXYGEN HEATER REAR

- Bank 1

|

P0141 |

Functional check |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

10 s |

Once per driving cycle |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

-

OXYGEN SENSOR FRONT

- Bank 2

|

P0153 |

Response Rate |

Switching frequency AND Quick output

change counter |

Same as P0133 |

|

Once per driving cycle |

|

P0154 |

Oxygen sensor inactive |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

60 s |

Continuous |

|

P2197 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

0.01 ≤ V < 0.4 |

30 s |

Continuous |

|

P2198 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

0.55 < V < 1.05 |

60 s |

Continuous |

|

P0151 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

< 0.01 V |

30 s |

Continuous |

|

P0152 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

≥ 1.05 V |

60 s |

Continuous |

-

OXYGEN SENSOR REAR

- Bank 2

|

P0160 |

Oxygen sensor inactive |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

60 s |

Continuous |

|

|

Transient test |

Oxygen sensor output voltage

|

V> 0.5 |

10 times |

Continuous |

|

|

|

|

V< 0.5 |

10 times |

Continuous |

|

P2272 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

0.01 ≤ V < 0.1 |

300 s |

Continuous |

|

P2273 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

0.07 < V < 1.05 |

300 s |

Continuous |

|

P0157 |

Oxygen sensor locked lean |

Oxygen sensor output voltage

|

< 0.01 V |

300 s |

Continuous |

|

P0158 |

Oxygen sensor locked rich |

Oxygen sensor output voltage

|

≥ 1.05 V |

300 s |

Continuous |

|

OXYGEN HEATER FRONT Bank 2

|

P0155 |

Functional check |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

5 s |

Once per driving cycle |

|

OXYGEN HEATER REAR Bank 2

|

P0161 |

Functional check |

Oxygen sensor output voltage

|

0.4 < V < 0.55 |

10 s |

Once per driving cycle |

INTAKE CAMSHAFT POSITION SENSOR

Bank 1

|

P0341 |

Response |

Cam sensor signal |

Repetition of the same sector of the cam signal after one revolution of thecrankshaft

|

20 times |

Continuous |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

EXHAUST CAMSHAFT POSITION SENSOR

Bank 1

|

P0366 |

Response |

Cam sensor signal |

Repetition of the same sector of the

cam signal after one revolution of the crankshaft |

20 times |

Continuous |

INTAKE CAMSHAFT POSITION SENSOR

Bank 2

|

P0346 |

Response |

Cam sensor signal |

Repetition of the same sector of the

cam signal after one revolution of the crankshaft |

20 times |

Continuous |

EXHAUST CAMSHAFT POSITION SENSOR

Bank 2

|

P0391 |

Response |

Cam sensor signal |

Repetition of the same sector of the

cam signal after one revolution of the |

20 times |

Continuous |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

|

|

|

|

|

crankshaft |

|

|

|

CRANKSHAFT POSITION SENSOR

|

P0336 |

Response |

Crank sensor signal |

If the same tooth of the crankshaft

|

|

|

|

|

|

|

|

flywheel is recognized after two

consecutive |

|

|

|

|

|

|

|

edges of the cam signal |

20 times |

Continuous |

|

SIGNAL SEQUENCE |

P1310 |

Response |

Intermittent loss of signal (blip)

|

coherence between sectors |

|

|

|

|

|

|

|

of the cam signal and specific teeth of

the crankshaft |

|

|

|

|

|

|

|

flywheel |

20 times |

Continuous |

-

MANIFOLD ABSOLUTE PRESSURE /

- BAROMETRIC PRESSURE

|

P0105 |

Functional check |

Comparison between manifold absolute pressure and barometric pressure

|

> 30 mmHg |

|

At the key on |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P1106 |

Functional check |

Comparison between ECU bank1 value and

ECU bank2 value |

> 25mmHg |

4 s |

Continuous |

|

|

P1107 |

Low input |

Manifold absolute pressure sensor

signal |

< 105 mmHg |

16 s |

Continuous |

|

|

P1108 |

High input |

Manifold absolute pressure sensor

signal |

> 809 mmHg |

16 s |

Continuous |

|

|

P1109 |

Low input |

Barometric pressure sensor signal

|

< 105 mmHg |

16 s |

Continuous |

|

|

P1110 |

High input |

Barometric pressure sensor signal

|

> 809 mmHg |

16 s |

Continuous |

|

BATTERY VOLTAGE |

P1101 |

Low output |

Battery voltage |

< 10 V |

20 times |

Continuous |

|

P1102 |

High output |

Battery voltage |

> 15 V |

20 times |

Continuous |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

|

ENGINE COOLANT TEMPERATURE |

P0116 |

Functional check |

Comparison between ECU LIE value and

CAN BUS value |

> 15 °C |

5 s |

Continuous |

|

|

P0117 |

Low Input |

Coolant temperature sensor |

< -20 °C |

250 s |

Continuous |

|

|

P0118 |

High input |

Coolant temperature sensor |

> 120 °C |

1 s |

Continuous |

|

IDENTIFICATION “LIE” ECU

|

P1601 |

Range check |

Pin detection |

No pin detected |

10 times |

At the key on |

|

INTAKE AIR TEMPERATURE |

P0111 |

Functional check |

Derivative Air temperature sensor

signal |

> 15 °C/0.5 sec |

5 sec |

Continuous |

|

|

P0112 |

Low input |

Air temperature sensor |

< -25° C |

1200 s |

Continuous |

|

|

P0113 |

High input |

Air temperature sensor |

> 120 °C |

1s |

Continuous |

|

DRIVE BY WIRE |

P0226 |

Functional check |

Data |

Component found failed |

|

Continuous |

|

|

P0227 |

Low input |

Throttle position signal |

< 0° |

5 s |

Continuous |

|

|

P0228 |

High input |

Throttle position signal |

> 81° |

5 s |

Continuous |

|

|

P1226 |

set in case of throttle malfunction

detected by ECU Bank 1 |

|

|

|

|

|

P1227 |

set in case of throttle malfunction

detected by ECU Bank 2 |

|

|

|

|

PEDAL POSITION |

P0121 |

Functional check |

Comparison between sensor “A” and

sensor “B” |

> 10% |

3 s |

Continuous |

|

P0122 |

Pedal position sensor “A” Low Input

|

Pedal position signal |

< Threshold |

5 s |

Continuous |

|

P0123 |

Pedal position sensor “A” High Input

|

Pedal position signal |

> Threshold |

5 s |

Continuous |

|

P0222 |

Pedal position sensor “B” Low Input

|

Pedal position signal |

< Threshold |

5 s |

Continuous |

|

P0223 |

Pedal position sensor “B” High Input

|

Pedal position signal |

> Threshold |

5 s |

Continuous |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

|

EVAPORATIVE EMISSION CONTROL SYSTEM

|

P0441 |

Insufficient Purge Flow |

Evaporative System Pressure

|

<Threshold |

3 s |

Once per driving cycle |

|

|

P0442 |

Leak detected |

Evaporative System Pressure

|

<Threshold |

20 s |

same as P0441 |

|

|

P0443 |

Purge Control Valve Malfunction

|

Feedback-test |

Incorrect data feedback |

|

Once per driving cycle |

|

|

P0446 |

Vent Control Valve Malfunction

|

Feedback-test |

Incorrect data feedback |

|

Once per driving cycle |

|

|

P0450 |

Pressure Sensor Malfunction

|

Evaporative System Pressure

|

< -1 mbar or > 1 mbar |

|

at Key-on |

|

|

|

|

Evaporative System Pressure

|

>4.9 V |

|

continuos |

|

|

|

|

Evaporative System Pressure

|

< 0.5 V |

|

continuos |

|

|

|

|

Evaporative System Pressure

|

< -15 mbar or > |

3 s |

Once per driving |

|

|

|

|

|

5 mbar |

|

cycle |

|

IDLE CONTROL SYSTEM |

P0506 |

Functional check |

RPM RPMf(TH2O) |

RPM < |

10 s |

Once per driving cycle |

|

|

|

|

|

< 840 rpm |

5 s |

Once per driving cycle |

|

|

P0507 |

Functional check |

RPM |

RPM > RPMf(TH2O) |

10 s |

Once per driving cycle |

|

|

|

|

|

> 1080 rpm |

5 s |

Once per driving cycle |

|

SERIAL COMMUNICATION |

P0600 |

ISO 9141 Line failure |

Data communications |

Incorrect data feedback |

|

Once per driving cycle |

|

INTERNAL CONTROL MODULE

|

P0605 |

Internal routine |

Data |

Component found failed |

|

Once per driving cycle |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

|

FUEL SYSTEM Bank 1 |

P0171 |

Fuel trim system too lean |

Fuel trim correction |

> +0.75 ms |

30 s |

Continuous |

|

|

P0172 |

Fuel trim system too rich |

Fuel trim correction |

< -0.75 ms |

30 s |

Continuous |

|

FUEL SYSTEM Bank 2 |

P0174 |

Fuel trim system too lean |

Fuel trim correction |

> +0.75 ms |

30 s |

Continuous |

|

P0175 |

Fuel trim system too rich |

Fuel trim correction |

< -0.75 ms |

30 s |

Continuous |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

-

CATALYST TEMPERATURE

- Bank 1

|

P1401 |

Catalyst overtemp.

1st level |

Catalyst temp sensor signal

|

> 900 °C < 940 °C |

1 s |

Continuous |

|

|

P1402 |

Catalyst overtemp.

2nd level |

Catalyst temp sensor signal

|

> 940 °C |

1 s |

Continuous |

|

|

P0427 |

Low input |

Catalyst temp sensor signal

|

< 20°C |

60 s |

Continuous |

|

|

P0428 |

High input |

Catalyst temp sensor signal

|

970°C |

|

At The Key on |

-

CATALYST TEMPERATURE

- Bank 2

|

P1405 |

Catalyst overtemp.

1st level |

Catalyst temp sensor signal

|

> 900 °C < 940 °C |

1 s |

Continuous |

|

|

P1406 |

Catalyst overtemp.

2nd level |

Catalyst temp sensor signal

|

> 940 °C |

1 s |

Continuous |

|

|

P0437 |

Low input |

Catalyst temp sensor signal

|

< 20°C |

60 s |

Continuous |

|

|

P0438 |

High input |

Catalyst temp sensor signal

|

970°C |

|

At The Key on |

|

CATALYST TEMPERATURE |

P1426 |

Functional check |

|Catalyst temp sensor signal

|

> 200°C |

60 s |

Continuous |

|

|

|

|

Bank1 - Catalyst temp sensor

|

|

|

|

|

|

|

|

signal Bank2| |

|

|

|

|

CAN COMMUNICATION |

P1602 |

Data failure |

Data communications |

Incorrect data feedback |

3 s |

Continuous |

|

THERMOSTAT |

P0128 |

Functional check |

Engine Coolant Temperature |

< 70 °C |

5 s |

Once per driving cycle |

|

SECONDARY AIR INJECTION Bank1

|

P0491 |

Functional check |

Oxygen sensor output voltage

|

V > 0.3 [V] |

2s |

Once per driving cycle |

|

SECONDARY AIR INJECTION Bank2

|

P0492 |

Functional check |

Oxygen sensor output voltage

|

V > 0.3 [V] |

2s |

Once per driving cycle |

|

SECONDARY AIR INJECTION

|

P0412 |

Electro Valve feedback-test |

Feedback-test |

Incorrect data |

|

Once per driving |

|

ELECTRO VALVE |

|

|

|

feedback |

|

cycle |

|

|

Component/System |

Fault code |

Monitor Strategy Description

|

Primary malfunction detection parameter

|

Fault Activation range |

Time length of the fault |

Frequency of check |

|

OIL TEMPERATURE

|

P0197 |

Low input |

Oil temperature signal output

|

< 20 bit |

2s |

Continuous |

|

|

P0198 |

High input |

Oil temperature signal output

|

> 1000 bit |

2s |

Continuous |

|

INTAKE VARIABLE VALVE TIMING CONTROL

Bank1 |

P1366 |

Functional check |

VVT position Target - VVT position

|

10 deg |

2s |

Continuous |

|

EXHAUST VARIABLE VALVE TIMING CONTROL

Bank1 |

P1367 |

Functional check |

VVT position Target - VVT position

|

10 deg |

2s |

Continuous |

|

INTAKE VARIABLE VALVE TIMING CONTROL

Bank2 |

P1368 |

Functional check |

VVT position Target - VVT position

|

10 deg |

2s |

Continuous |

|

EXHAUST VARIABLE VALVE TIMING CONTROL

Bank2 |

P1369 |

Functional check |

VVT position Target - VVT position

|

10 deg |

2s |

Continuous

|

|