| |

|

|

|

|

||

Repairing Koni Front Lifting System in a Diablo

|

The Koni Front Lifting System in a Diablo

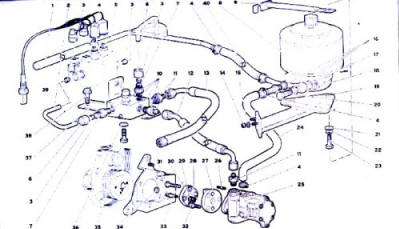

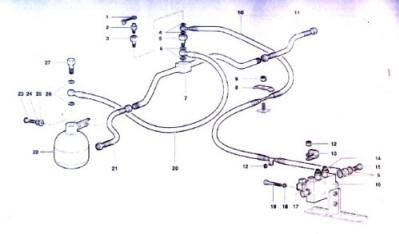

As can be seen in the above diagrams the oil for the front rising system is pumped from the power steering reservoir through a valve system to both front shocks. Even tough the same oil reservoir is used by both the front lifting system and the power steering system they behave quite separately. The same pump is used to pressure the oil in both systems however. The onboard LIE computer carefully monitors the oil pressure put out by the pump required to raise the car. This pressure goes from less than 20 Bar (~260 PSI) to over 100 Bar (~1500 PSI) as the car is raised. You need this kind of pressure to raise such a heavy car with such small hydraulic pistons (in the shocks). To monitor the pressure there are two pressure sensors, a MIN pressure and MAX pressure sensor switch. These are shown in Figure 4. They are clearly labeled in the steel block they are screwed into. This assembly is located just above the gas tank in the side compartment of the engine area. The Min switch has a adjustable screw painted red. The Max switch screw is painted blue. These screws should normally not be tampered with. They are factory set to set the cutoff pressures for the front hydraulic lifting system and are very sensitive. A slight adjustment of 5 degrees has a big effect see below. The way the system works is as follows: The Min switch is a "normally open" switch so when the car is in its (normal) low position, this switch is set open. Removing the two wire connections and measuring the resistance across the switch should show an open connection when the car is in its normal low position. The Max switch on the other hand is a "normally closed" switch. When the car is in the normal (lowered) position removing the two wire connections should show essentially no resistance across the switch contacts. When the car is raised. The min switch should close (as the pressure passes above 40 Bar) and remain closed. When the car is full up (and the pressure is over 80 Bar) the Max switch will open. Both switches should remain in these states while the car is raised. They reverse back to their original states when the car is lowered. Both switches have a grey/red wire connector that is connected to ground for both switches. You can check the switches are opening and closing correctly by measuring the voltage of the violet/white lead on the Min switch and the green/black lead of the Max switch during the raising and lowering process. To see the voltage changes attach a voltmeter clip to the switch contact (at the same time making sure the wire contact supplying the voltage to the switch is not disconnected) and tape the meter to the car window as shown in figures 5 and 6. Then raise the front of the car. For the Min switch the voltage should be +12V quickly going to 0V and staying there as the car is rising. For the Max switch on the other hand the voltage will be 0V going to +12 volts and staying there once the car is full up.

Oil Pressure Failure: If the power steering pressure pump is not capable of delivering the 1500+ PSI pressure the car can not be raise correctly. To check this you will need to monitor the oil pressure being sent to the front shocks system. Fortunately Lamborghini provides a location to tap into the system. It is behind the panel in the front trunk as shown in figures 7 and 8. This is actually an air bleed screw to get air out of the system during an oil change. To measure the oil pressure we will construct a custom oil pressure gage. First let me warn you that we are talking about very high oil pressures here. A pipe burst at 1500 PSI will spray oil everywhere and potentially cause bodily injury. Even when the car is lowered the oil pressure in the system is still ~260 PSI.

To attach this gage to the car system you must first relieve the pressure in the system by attaching a hose and container to the air bleed and opening it slowly. See figure 9. When the oil stops flowing remove the air bleed vent. This leaves you with a female fitting. Fortunately this is exactly the same 0.4" treads that are used in brass tubing fittings found in most (US) hardware stores. You need to setup an assembly as shown in figures 10 and attached it to the car as shown in figure 11. You have to attach the vertical stem first, then attach the stopcock and gage. All joints should be Teflon taped and quite tight. This process can be quite messy. It's a good idea to cover the whole area with plastic covering and wrap a rag around the base of the air bleed area to absorb runoff oil. With the assembly in place (and the stopcock open) start the engine and raise the car. Quickly check for leaks! With the car full up, the oil pressure should go to about 1400 PSI and then fall back to ~1200 PSI (fig 12). When the car is lowered the pressure drops and stays at about 250 PSI (fig 13). If you do not see these numbers you may need to replace the power steering pump. Now to put things back you need to relive the oil pressure in the system. Close the stopcock and carefully remove just the pressure gage (fig 14). Then put a container under the stopcock and open it. When the oil stops flowing remove the vertical brass tube and put back the Lamborghini air bleed. Tighten it down. You will also have to add some power steering oil to the reservoir in the back of the car. If the oil did not come within the above pressure values you either have a failing power steering pump or faulty sensor switches (see below). As a side note, perhaps the reason these KONI shocks tend to leak is that they always have 250 PSI pressure in them even when the car is in the lowered position. It's not clear to me why this is so. If you vent off the pressure (as described above) the pressure will stay at 0 PSI until the next time the car is raised -- even when the power steering is used. Perhaps the Min oil pressure sensor switch could be adjusted downwards. Some day maybe I will experiment!

To replace the Min switch you must release the oil pressure with the oil/air bleed system as described above. You them need to drain the power steering fluid reservoir. I find the easiest way to do this is to siphon it out using a brake fluid vacuum pump to get things started. To be on the safe side you should surround the Min/Max switch block area with some rags (fig 16). You don't want oil dripping on top of the gas tank area below. Now we are ready to remove the Min switch. Remove the connecting wires and with a 25mm socket carefully screw out the assembly see fig 17 & 18 (Note in fig 17 rags were removed for photograph). Be real careful not to loose the brass/rubber gasket (fig19). Transfer this gasket to the new unit and screw the new unit back in. The Lamborghini part number for this switch is #51009370 (It costs ~$245*). Reconnect the wires. Fill the power steering oil reservoir to within 1 inch of the top. Do not overfill this reservoir. If you do it will overflow through a small bleed hole (figures 20 & 21) in the rubber top knob and drip down on to the compartment below. You are now ready to test the lifting system. The first time you start the system up, it seem to take a little longer to raise the car. This is because the pump is building the pressure up from 0 PSI to the normal base 250 PSI. The car starts to rise from then on. This can be easily seen if you use the oil pressure gage setup I described above. It may be necessary to bleed air out of the system -- though I have not found this to be so -- using the oil/air bleed nozzle I described above.

* The Lamborghini "Pressure Regulator - Min" costs $250.00. Interestingly what looks like the exact same switch sold by PLV Ltd in England costs 25 Euros. See http://www.pvl.co.uk/datafaxes/1021 - PMN.pdf. Lamborghini parts pricing again!

|

||||||||

|

|

|

||||||

| Fig 4. Min & Max pressure switches | Fig. 5. Testing Max pressure switch | Fig 6. Attach voltmeter to door window | ||||||

|

|

|

||||||

| Fig 7. Oil bleed nipple | Fig 8. Close-up of oil bleed nipple | Fig 9. Relieve oil pressure |

||||||

|

|

|

||||||

| Fig 10.

Custom Fitting to measure oil pressure

|

Fig 11. Custom fitting in place | Fig 12. Car raised. 1100 PSI | ||||||

|

|

|

||||||

| Fig 13. Car lowered

250 PSI

|

Fig 14. Remove gage. Release pressure | Fig 15. Short Min switch leads | ||||||

|

|

|

||||||

| Fig 16. Surround

switch block with rag

|

Fig 17. Remove Min pressure switch | Fig 18. Min switch removed | ||||||

|

|

|

||||||

| Fig 19.

Min pressure switch and gasket

|

Fig 20. Air bleed hole on steering fluid reservoir | Fig 21. Air bleed hole on steering fluid reservoir | ||||||